By Daniel Peterson

Dan will present Designing for Dry Stone Walling in the Landscape at ELA’s Conference & Eco-Marketplace on March 4.

Beginning to Understand Dry Stone Walls in the Landscape

Figure 1: Heiau in Hawaii built with basalt.

In 2018, UNESCO inscribed the art of dry stone walling knowledge and techniques in its list of Intangible Cultural Heritage of Humanity stating, “Such structures testify to the methods and practices used by people from prehistory to today to organize their living and working space by optimizing local natural and human resources. They play a vital role in preventing landslides, floods and avalanches, and in combating erosion and desertification of the land, enhancing biodiversity and creating adequate microclimatic conditions for agriculture.”

My personal journey with stone started at a very early age on a farm in central Minnesota and then progressed into using stone in the landscape. I became acquainted with the Dry Stone Walling Association (DSWA), which sparked the journey into ‘traditional’ dry stone construction through a client recommendation. Dry stone walls are stone structures built with techniques free of any mortar or adhesive. Dry stone structures rely on the physics of gravity and friction to create a structurally sound feature.

The Cultural Ubiquity of Stone Walls

Figure 2: Slope terracing along the Kumano Kodo pilgrimage trail in Japan. The mountainside is currently used for forestry production and in a region prone to earthquakes.

Dry stone has been used by virtually every culture worldwide for thousands of years. Some structures have been standing for over millennia, such as Scelilig Mhichil in Ireland, built between the sixth and eighth centuries. Many of the fence walls in the British Isles date to the times of Roman occupation. In the Americas, we can see Machu Picchu and the Mayan structures. The Pacific has Heiau structures throughout the Hawaiian Islands built prior to European influence (Figure 1). Africa has Great Zimbabwe, Asia has the terracing and feudal castles in Japan (Figure 2), to name but a few. The same construction principles apply throughout the world regardless of location or culture; only the stone types and shapes change.

European farming practices actively used dry stone walls to enclose pasture and field spaces with the cleared fieldstone; the immigrants’ techniques and knowledge were imported to the U.S.. Dry stone use as a common fencing and structural foundation practice began to decline during the 1800s, coinciding with the discovery of easily produced Portland Cement in the1820s and barbed wire in the mid-1800s. The advent of cheaper and faster construction methods led to the loss of knowledge and skill to construct dry stone features, especially before the 1960s, because most expertise was passed down through apprenticeships and family trade practices. A resurgence in the craft began with organizations like the Dry Stone Walling Association of Great Britain. Understanding the importance of preserving the historical craft became apparent, especially in the UK where there are 1,000s of miles of dry stone walls in need of repair.

Enduring Construction

Properly constructed dry stone walls can last more than a lifetime, even longer than mortared and concrete walls. Properly built dry stone walls can flex and move with the ground as it shifts during freeze-thaw cycles or settling, whereas mortared walls are rigid and tend to crack when the ground shifts. Dry stone walls also allow moisture to pass through the structure, whereas mortared or concrete walls will trap moisture, leading to structural failure over time. Properly constructed dry stone walls rely on the forces of gravity and friction to create a permeable structural system with strength and ductility, allowing for a long service time span (McCombie et al., 2016).

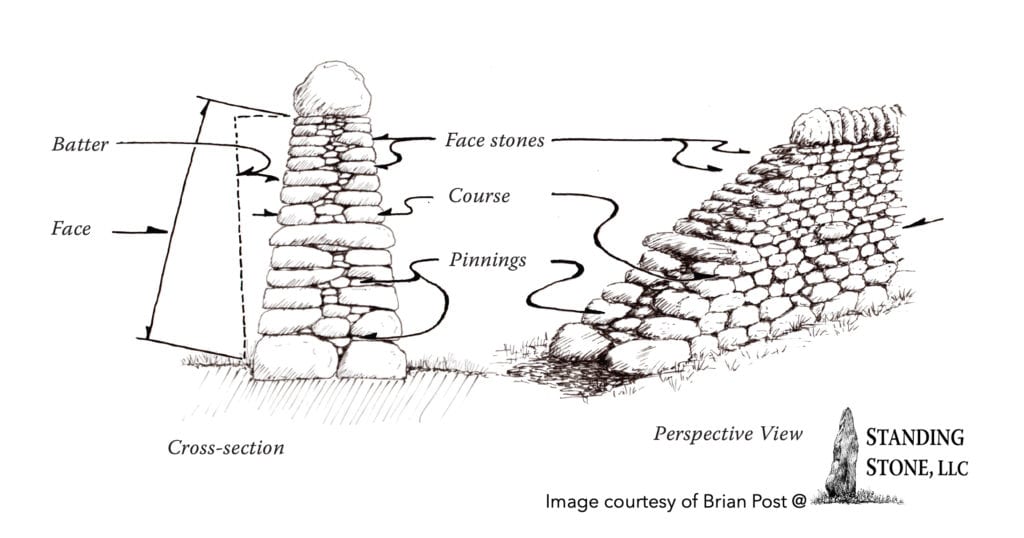

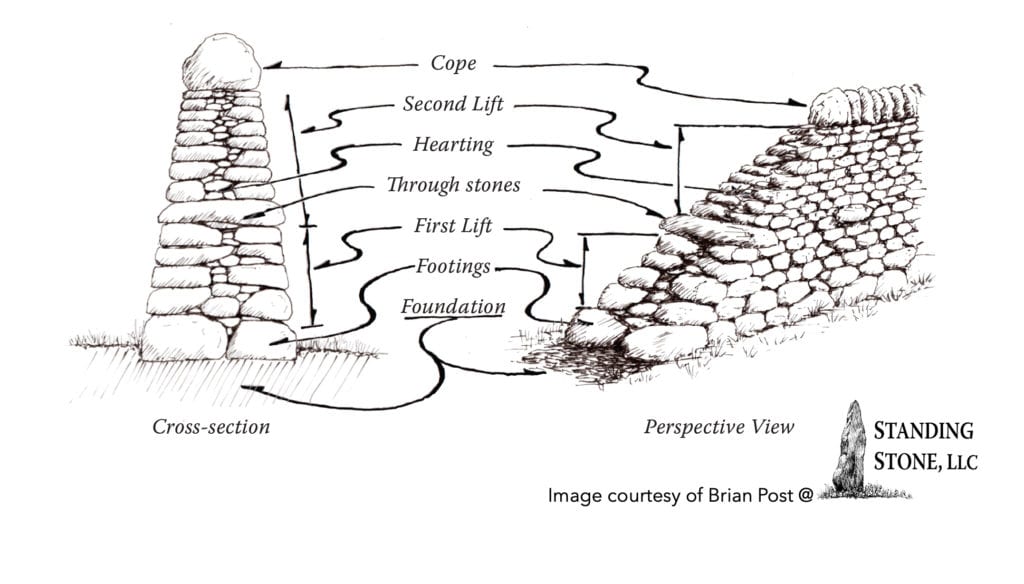

Dry stone walling is a systems approach to construction. The individual stones in a wall are part of a system construction, but by themselves are not dry stone. How all of the stones perform together is what makes a dry stone structure. Stone construction works much like how permeable paver technology performs with the individual paver not being permeable, but the system installed together is permeable. The terminology used in dry stone walling is essential when understanding what a drystone wall structure is. Please keep in mind the diagrams and details presented refer to freestanding double-sided walls. Additional details are needed when designing structural foundations, corners, and other features in dry stone.

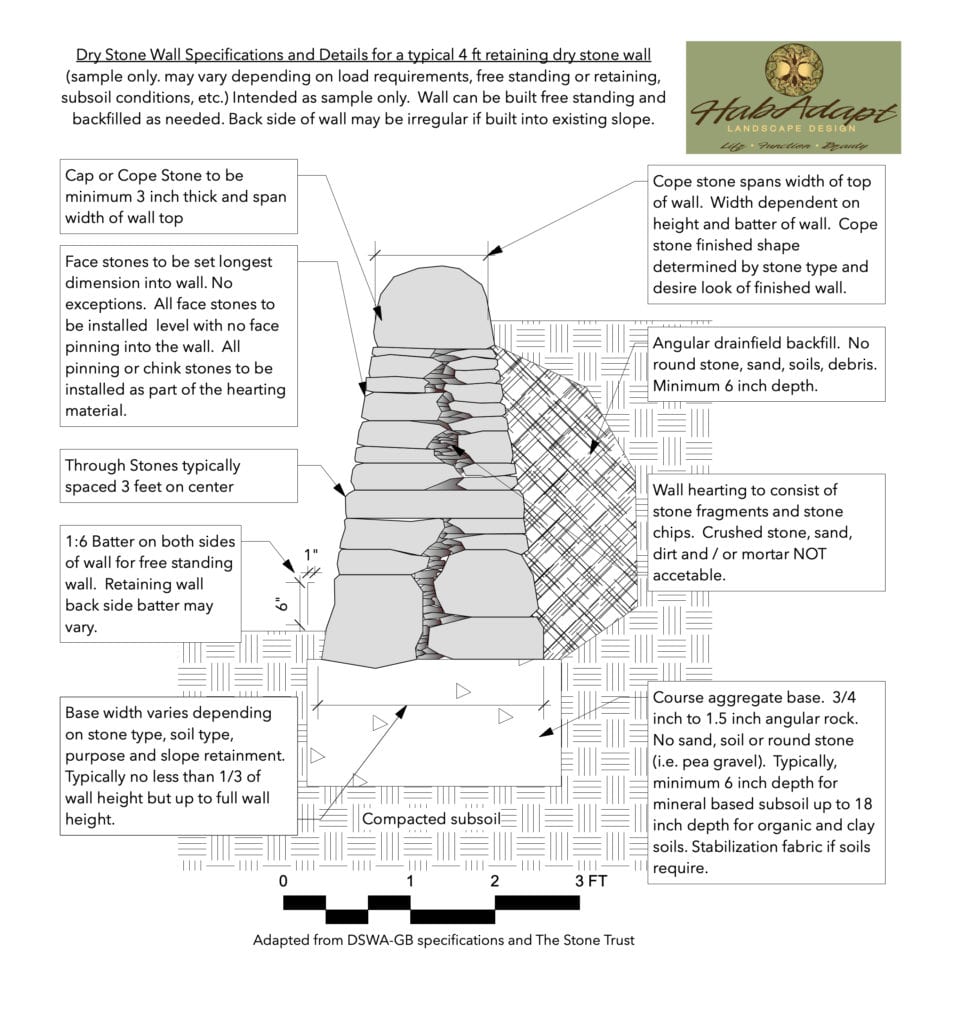

Foundation – The substructure on which the wall is built (Figure 4). The foundation may be the virgin soil if it has enough support structure or crushed stone. Typically, larger coarse aggregates are used for crushed stone base materials.

Footing or foundation stones – The larger boulders at the bottom of the wall are capable of carrying the full weight of the wall (Figure 4).

- Figure 5a: Samples of length in where the length of the stone running into the wall along with batter will increase the stability of the wall as it is constructed and reduce the chance of tipping. All stones should have good contact.

- Figure 5b: Sample of trace walling. The narrow width of the wall and crushed stone installed behind this wall was causing it to fail in the landscape after being in place for less than 10 years. Notice how the batter has begun to inverse from a positive batter.

Building stone, face stone – The stone used for building the outer sides of the wall (Figure 3 &4). Typically, the larger the stone, the lower in the wall it should be placed. The stones are set in courses and can vary in size. These stones should be placed length into the wall to increase the density of the face of the wall (Figure 5a and 5b).

Figure 6: One to six batter. The stone in the left image is level bedded limestone. The stone in the right image is round glacial erratic boulders.

Hearting or packing – The smaller stone used to pack the space between the two faces of a structure. The hearting stone should be packed as tightly as possible within the wall without pushing the face stones out of batter. Insufficient hearting in the wall structure can cause the wall to collapse in on itself. Typically, the largest piece that fits the void tightly is best. Hearting should be irregular in shape and not round. Hearting stone should be large enough that it is not easily shoveled. Small hearting material such as river rock, gravel, or 3/4-inch clear stone tends to act like ball bearings inside the wall and will push the face stones out. Proper hearting material increases friction and adds more points of contact within the wall, locking the stone in place (Figure 4).

Through stone – The long stones that span the width of the wall to tie a double-faced wall together (Figure 4). The spacing varies depending on the height of the wall, type of stone being used, etc.

Figure 7: Wall samples showing two types of coping. The top image is free standing with vertical coping, whereas the bottom image is retaining with a horizontal cope. The bottom image is the wall from Figure 5b after it was rebuilt in the double-sided method. The existing stone was reused and new stone was incorporated to increase the wall mass to appropriate dimensions.

Pinning – The wedge stones used on the inside of the wall to level the face stones as needed (Figure 3). Pinning should not be used on the face of the wall since it tends to migrate out of the wall potentially leading to premature wall failure; upper face stones are no longer supported. Pins installed on the inside of the wall will be held in place by the hearting.

Copestones – The stones used to cap the top of the wall (Figure 4 & 7). Copestones span the width of the wall. Ideally, they are set with the narrow edge down on the wall to increase downward pressure.

Batter – The inward slope of the wall from the foundation to the copestone (Figure 3). Usually, I use a 1:6 batter (1 inch in for every 6-inch rise); an increased batter will essentially move the center of gravity towards the center of the wall and away from the face allowing for more stability in the finished wall (McCombie et al. 2016).

Figure 8: One stone over two and two stones over one should be followed to maximize stone to stone contact and reduce the chance of running or cross joints. Running joints will create weak points in the wall.

Dry stone walls should follow five basic rules (The Stone Trust and DSWA). First, all stones should be placed length into the wall to increase the mass and strength in the wall. Stones placed with the long edge as the face will tip out of the wall over time. Second, all hearting (packing) stones and pin stones should be placed inside the wall, not the exterior of the wall. Third, all joints should be crossed to reduce the chances of running joints and stretcher stones (Figure 8). Stones should generally be placed one over two and two over one. Avoid stones placed over more than two stones since the center stones will not remain tight in the wall and will migrate out of the wall in time. Fourth, the top of the wall stone should be set level length into the wall, and if pinning is needed it should be installed under the stone to lift the back up to a level plane. Finally, stones should be built to the desired line or batter in an even plane as the wall is constructed. Concave or convex batters can influence the stability of the stones placed above and within the completed wall. Keep in mind the rules are general guidelines and can be modified depending on the skill of the dry stone craftsperson as well as the type of stone being used.

The Designer’s Role

Successful implementation of dry stonework requires a couple of key things from those of us who are landscape designers and architects. Promote and specify certified or trained craftspeople and consultants for installing the designed project. The Stone Trust and DSWA have lists of certified and trained wallers listed on their websites. When designing the dry stone feature, be sure to use correct details and specifications (Figure 9). Properly trained craftspeople and concise designs will greatly improve the longevity of the project.

Detailed information is needed when designing dry stone features (McCombei et al. 2016), especially when submitting plans for outside vendors to install. The dimensions for this feature would be added and depend on the stone being used, final appearance desired, the function of the feature as well as the soils present at the location.

Dry stone offers numerous advantages for the ecologically conscious designer. The walling methods tolerate movement and have tensile strength. The materials used can often be sourced locally and sometimes from the same space the feature is being constructed. Dry stone walls offer structural support for other landscape features and, when properly constructed, they have significant longevity compared to mortared and concrete wall structures. The materials used are a simple material that can be reused for the same purpose, whereas concrete and mortared wall systems often are difficult to repurpose for the same feature.

Figure 10: The Stone Trust offers various training opportunities, many of which are held in the New England area(Pre-Social Distancing.)The Stone Trust is also developing expansion workshop sites with partners such as the Minnesota site pictured above.

Education and Training Resources

The Stone Trust thestonetrust.org

The Stone Trust thestonetrust.org

The Stone Trust is a 501(c)3 whose mission is to preserve and advance the craft of dry stone walling through education and training. The Stone Trusts’ vision is to promote the incorporation of durable, energy-efficient stone materials into contemporary design and cherished historical structures in support of resilient and diverse local economies (Figure 10).

The Dry Stone Walling Association (DSWA) of Great Britain dswa.org.uk

The Dry Stone Walling Association (DSWA) of Great Britain dswa.org.uk

The DSWA is a registered charity that works to advance education in the craft and heritage of dry stone walling for the public benefit.

The Stone Foundation stonefoundation.org

Dry Stone Conservancy drystone.org

Please note there are numerous international organizations specializing in dry stone construction training and education.

Literature Cited

[DSWA] Dry Stone Walling Association of Great Britain. 2004. Dry Stone Walling Techniques & Traditions. Cumbria, United Kingdom. Dry Stone Walling Association.

McCombie PF, Morel JC, Garnier D. 2016. Drystone Retaining Walls: Design, Construction and Assessment. Boca Raton, Florida: Taylor & Frances Group.

(UNESCO) United Nations Educational, Scientific and Cultural Organization. 2018. https://ich.unesco.org/en/RL/art-of-dry-stone-walling-knowledge-and-techniques-01393

Figure and Image Credits

Figures 1, 2, 5a, 5b, 6,7,9, 10 Daniel Abdon Peterson MAg. HabAdapt Landscape Design.

Figures 3, 4, 5a (drawing), 5b (drawing), 8. Brian Post LA. Standing Stone LLC

About the Author

Daniel Abdon Peterson MAg Principle, HabAdapt Landscape Design. Dan is a Minneapolis based landscape designer who focuses on ecologically sound, full-service landscape design and installation. A majority of his projects involve restorative practices incorporating native plant communities, permaculture practices, water management, and dry stone construction.

Daniel holds a level III, Advanced dry stone craftsman certification, and dry stone teaching certification with the Dry Stone Walling Association of Great Britain. Daniel is also currently serving as the President of the Board of Directors for The Stone Trust advocating for the recognition and advancement of the historic practice of Dry Stone construction. For more information about Daniel or HabAdapt Landscape Design please check out his website habadapt.com or Instagram HabAdapt.

***

Each author appearing herein retains original copyright. Right to reproduce or disseminate all material herein, including to Columbia University Library’s CAUSEWAY Project, is otherwise reserved by ELA. Please contact ELA for permission to reprint.

Mention of products is not intended to constitute endorsement. Opinions expressed in this newsletter article do not necessarily represent those of ELA’s directors, staff, or members.